Standing Seam Metal Roof in Southwest Florida (2026), Gauge, clip systems, and what matters near the coast

If you own property in Fort Myers, Naples, Cape Coral, or Sarasota, your roof doesn’t get a “normal” life. Salt haze rides the wind, summer heat bakes fasteners and sealants, and hurricane season tests every edge detail.

A standing seam metal roof can be one of the best long-term systems for coastal Southwest Florida, but only when it’s specified as a full assembly, not as a single buzzword like “24-gauge.” Gauge matters, clip choice matters, and workmanship matters even more.

This guide breaks down the real tradeoffs in 2026, in plain language, so you can compare bids and ask better questions during a roof inspection.

Near the Gulf, the roof fails at the edges and fasteners first

Coastal exposure and wind zones vary across Southwest Florida, even within the same county (created with AI).

Coastal exposure and wind zones vary across Southwest Florida, even within the same county (created with AI).

In coastal Florida, the “roofing material” is only the top skin. What keeps water out during wind-driven rain is the system below it: underlayment laps, sealed transitions, flashing, and the way the perimeter is built.

Here’s what changes when you’re near the coast:

Salt corrosion is relentless. Coastal air attacks scratches, cut edges, and low-grade fasteners. Even the best panel won’t age well if the wrong screws, rivets, or clips are used. For a manufacturer view of corrosion and install details, see metal roofing guidance for coastal areas.

Wind uplift is not “one number.” Wind pressure is higher at corners and edges than in the field of the roof. That’s why two homes a mile apart can need different clip spacing and edge metal fastening, even with the same panel gauge.

Thermal movement is bigger than people think. Metal expands and contracts daily. Long panel runs, dark colors, and hot attic temps increase that movement. Clip selection and layout decide whether the roof glides smoothly or fights itself.

Also, remember that a standing seam system isn’t the right answer for every building shape. A flat roof on an addition or a low-slope commercial roof often does better with a membrane or coating system designed for ponding and drains, while a steep-slope home might be comparing a metal roof against a shingle roof , tile roof , or stone coated steel roof for budget and style. If you’re weighing options for a roof replacement , this metal roof vs shingle roof comparison helps frame the decision in Southwest Florida terms.

22 vs 24 vs 26 gauge in Southwest Florida, what you gain and what you don’t

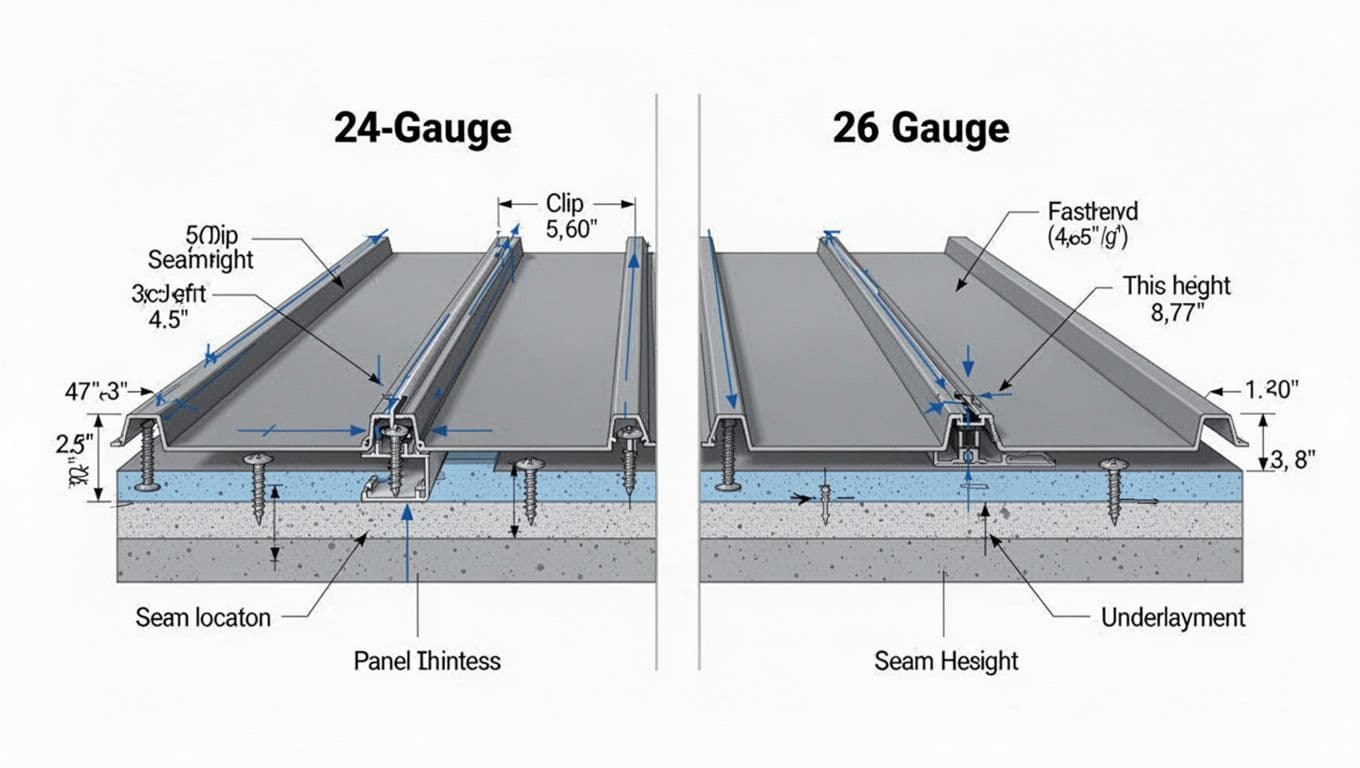

Cross-sections show how thickness, seam shape, and attachment work together (created with AI).

Cross-sections show how thickness, seam shape, and attachment work together (created with AI).

Gauge is thickness for steel panels (lower number equals thicker). In Southwest Florida, the most common discussions are 26-gauge vs 24-gauge, and sometimes 22-gauge for higher-demand projects.

Thicker panels can resist oil-canning a bit better, take foot traffic better, and may improve wind performance. But gauge alone doesn’t “rate” a roof. A 26-gauge panel installed with tested clips, tight spacing, correct substrate attachment, and strong edge details can outperform a poorly detailed 24-gauge install.

Cost and availability also matter in 2026. A jump from 26 to 24 gauge usually raises material cost and can raise labor if the system uses heavier clips or a different seam method. The best approach is to match gauge to the building’s exposure, geometry, and approved assembly, then spend your attention on the details that actually control failures.

Below is a fast comparison you can use during bid reviews.

| Item | Typical SWFL use | What it tends to improve | What to confirm near the coast |

|---|---|---|---|

| 26-gauge steel | Many residential roofs | Lower cost, easier forming | Must be a tested assembly with correct clip spacing and edge metal |

| 24-gauge steel | Coastal homes, longer runs | Better stiffness, often higher tested pressures | Verify approvals match your wind zone and roof deck attachment |

| 22-gauge steel | Select high-demand jobs | Highest stiffness, impact resistance | Added weight and cost, confirm system is approved for your build |

| Fixed clips | Shorter panel runs, controlled movement | Simple, rigid attachment | Can stress panels if runs are long or temps swing |

| Floating (sliding) clips | Longer runs, hotter roofs | Allows thermal movement | Verify tested uplift values with the exact clip type and spacing |

Two more points people miss:

- “Steel vs aluminum” is a coastal conversation. Aluminum doesn’t rust, but it can dent easier and still needs the right fasteners and coatings. Steel relies more on coating quality and cut-edge care.

- The panel is only half the story. Underlayment choice, sealed penetrations, and perimeter metal are where water finds its way in.

If you want a plain-language view of what standing seam systems look like in practice, start with standing seam metal roofing in Cape Coral and use it as a checklist while you review proposals.

Clip systems, approvals, and why wind rating depends on the whole assembly

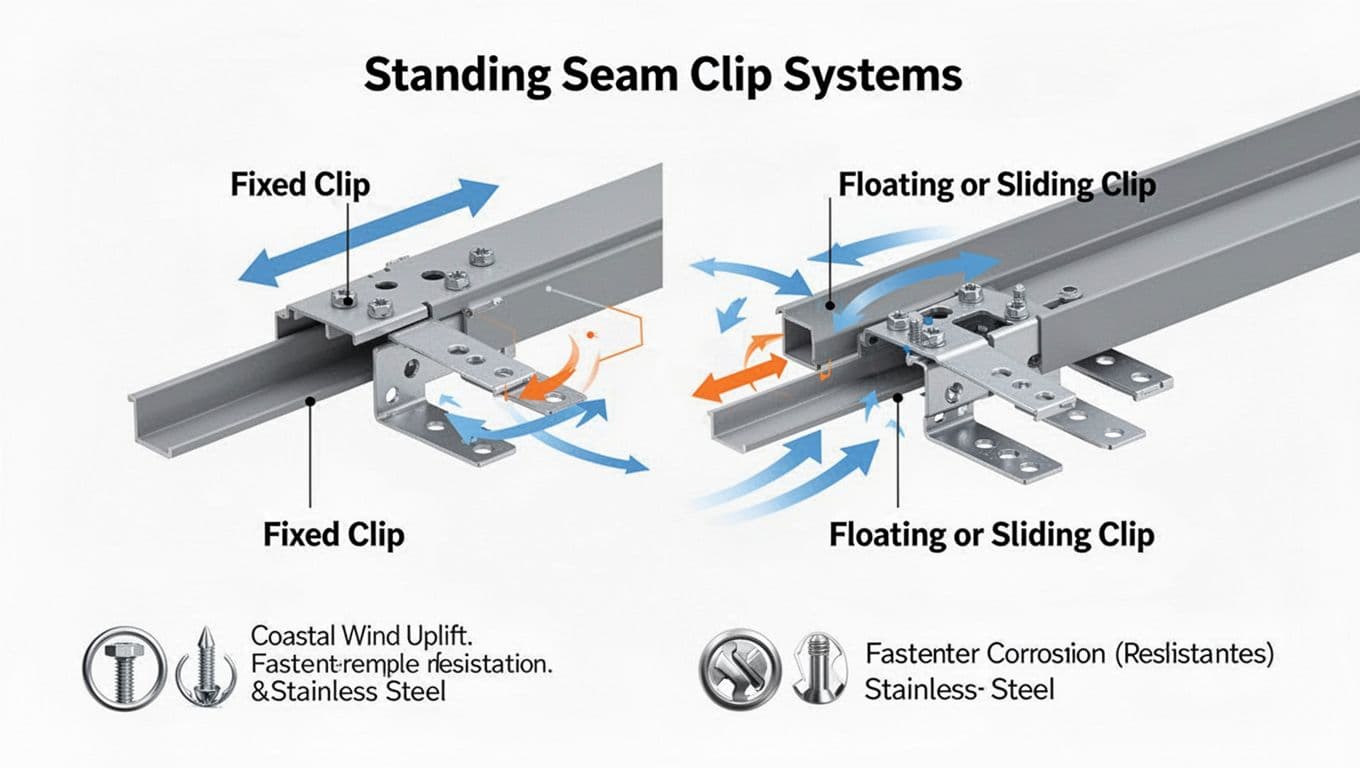

Fixed and floating clips handle expansion differently, and that affects long-term performance (created with AI).

Fixed and floating clips handle expansion differently, and that affects long-term performance (created with AI).

Clips are the “hands” holding a standing seam roof down. They transfer wind uplift into the deck and structure. They also manage thermal movement, which affects noise, waviness, and long-term seam stress.

When people ask, “Is 24-gauge required near the water?” the better question is: “What tested assembly meets my required design pressures?” Those pressures come from the building’s height, roof shape, and exposure, and they’re highest at corners and edges. Your roofer should be able to explain how the panel, clip type, clip spacing, fasteners, and substrate work as one system.

In 2026 Florida work, look for documentation that ties the roof system to approvals. Depending on the jurisdiction and project, that may include Florida Product Approval listings or Miami-Dade NOAs.

- For a quick way to review Florida listings by approval number, many specifiers use tools like a Florida Product Approval listing page to see what documents and limits apply.

- For Miami-Dade, manufacturers and suppliers often summarize what products carry approvals, like this Miami-Dade approved products overview.

- If you want to see what an NOA looks like, here’s an example PDF: Miami-Dade NOA document. (The key for most owners is that “no deviations” rule, the assembly has to match the approval.)

A simple coastal spec list to discuss with your roofer

- Panels and seams : Standing seam profile suited to your slope, with mechanically seamed or approved snap-lock as required.

- Clips and fasteners : Stainless or approved corrosion-resistant fasteners where specified, and clip spacing that matches the tested assembly.

- Underlayment : High-temp, wind-rated underlayment with correct laps and sealed transitions at valleys, edges, and penetrations.

- Edge details : Heavier-gauge drip edge and fascia metal where required, with fastening patterns that match the approval.

- Ventilation : Balanced intake and exhaust to reduce attic heat load and moisture.

- Dissimilar metals : Avoid galvanic reactions, confirm compatible flashings and accessories.

For property managers balancing multiple assets, this is where a good roofing company earns its keep. A strong bid should explain the assembly, not just the panel. It should also include a realistic plan for ongoing roof inspection , especially after major wind events. If you’re managing multiple buildings, bookmarking a single place for service options helps, like these roofing services in Southwest Florida.

Disclaimer: This article is general education, not engineering advice. Always consult a licensed Florida roofer and, when required, a Florida professional engineer for site-specific wind design, product approvals, and permitting requirements.

Conclusion

A standing seam metal roof can be an excellent choice near the Gulf, but the best results come from getting the whole assembly right. Gauge is part of the decision, clip systems control movement and uplift, and coastal durability depends on coatings, fasteners, and edge details.

If you’re planning a roof replacement or scheduling a roof inspection in Southwest Florida, ask to see the tested assembly and approvals, then compare bids based on details, not just panel thickness. A well-specified standing seam system should read like a plan, not a guess.